Understanding Direct Metal Mastering – Vinyl Record Pressing

Vinyl records have seen a resurgence in popularity, cherished by music enthusiasts for their unique sound and nostalgic appeal. At Solid-Merch, we are dedicated to providing high-quality vinyl pressings using the Direct Metal Mastering (DMM) technique. In this post, we’ll explain how DMM works and why we have chosen this method for our pressings.

History of Vinyl Pressing

The process of pressing custom vinyl records has evolved significantly since its inception in the early 20th century. Initially, records were made using shellac, but vinyl became the preferred material due to its durability and superior sound quality. Over time, the technology for creating vinyl records improved, leading to the development of various mastering techniques, including DMM.

What is Direct Metal Mastering (DMM)?

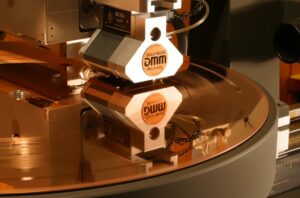

Direct Metal Mastering is a technique where the audio is cut directly onto a metal disc, typically copper, instead of the traditional lacquer-coated aluminum disc. This method, which emerged in the late 1970s, offers a distinct approach to vinyl mastering, and it’s the technique we exclusively use at Solid-Merch for our custom vinyl record pressings for independent bands and labels.

The DMM Process

The DMM process involves several detailed steps to ensure the production of high-quality custom vinyl records.

- Cutting the Master: In DMM, the audio signal is fed directly to a cutting lathe equipped with a diamond stylus. This stylus engraves the audio grooves into a copper-coated disc. The precision of this process helps in accurately capturing the audio details.

- Electroplating: After the master is cut, it undergoes electroplating. The copper master is coated with a layer of nickel to create a negative image of the grooves, known as the father. This father is then used to produce a positive image (the mother), which can create multiple stampers.

- Manufacturing the Stamper: The stamper is the final negative copy used to press the vinyl records. It’s created from the mother and is mounted onto the pressing machine. The stamper’s grooves mirror the original audio, ensuring high fidelity during the pressing process.

- Pressing the Vinyl: The stamper is placed into a hydraulic press, along with a puck of vinyl material. Under heat and pressure, the vinyl is pressed into the grooves of the stamper, creating the final record. The excess vinyl is trimmed off, and the record is cooled and inspected for quality.

Why Solid-Merch Uses DMM

At Solid-Merch, we aim to provide our clients with high-quality vinyl pressings that meet their specific needs. Here are some reasons why we have chosen to use DMM:

- Detailed Sound Reproduction: DMM allows us to capture fine audio details, providing a clear and precise sound that many of our clients appreciate.

- Efficient Production: The DMM process can streamline production, helping us to meet deadlines and deliver products in a timely manner.

- Durability: The metal masters used in DMM are robust, which helps in producing consistent, high-quality pressings over longer runs.

Considerations for DMM

While we at Solid-Merch value the benefits of DMM, we understand that different mastering techniques may be preferred by different audiophiles and music producers. We are always open to discussing the best approach for each project to ensure the final product aligns with our clients’ expectations.

Real-World Applications

Many of the records pressed at Solid-Merch using DMM have been well received by artists and fans alike. By offering DMM, we provide an option that captures the intricacies of audio recordings in a way that some of our clients prefer.

Direct Metal Mastering is the method we use at Solid-Merch to press high-quality vinyl records. By understanding the DMM process and its benefits, we can better serve our clients and meet the diverse needs of the music community. Whether you’re an artist, a producer, or an audiophile, we are here to help you achieve the sound and quality you desire in your vinyl pressings.